The Facts About Digital Printing Uncovered

The Facts About Digital Printing Uncovered

Blog Article

The Only Guide for Digital Printing

Table of ContentsSome Ideas on Digital Printing You Need To KnowThe Definitive Guide for Digital Printing3 Easy Facts About Digital Printing DescribedDigital Printing Fundamentals ExplainedThe Best Guide To Digital PrintingThe smart Trick of Digital Printing That Nobody is DiscussingFascination About Digital PrintingThe Definitive Guide to Digital Printing

Personalization additionally enables organizations to stick out in a crowded market by producing unique marketing products that separate them from their rivals. One of the primary benefits of digital printing is the capacity to print variable data. Each published item can be unique, enabling services to produce customized marketing materials that talk straight to their target market.Digital printing additionally enables customization in the layout of advertising products. With digital printing, companies can produce designs that are distinct and tailored to their particular demands. This can include tailored graphics, typefaces, and formats that can assist to distinguish them from their competitors. Another advantage of digital printing is the capacity to publish as needed.

Facts About Digital Printing Revealed

By printing smaller amounts of advertising and marketing products, organizations can minimize waste and avoid the demand for excess inventory. Digital printing is likewise flexible.

By making use of different materials and formats, services can create one-of-a-kind marketing materials that attract attention from their competitors and bring in focus from their target market. Digital printing additionally uses uniformity. With standard printing approaches, there is commonly variant in between prints because of differences in ink coverage, stress, and other factors.

This consistency can help build client depend on and reputation, showing that the business is devoted to offering high-grade materials. Consistency is particularly vital for businesses that intend to build client trust and credibility. By ensuring that every print is consistent, services can reveal that they are devoted to giving high-grade products and paying focus to the information.

The Only Guide for Digital Printing

In enhancement, electronic printing produces less waste since it can publish as needed and in smaller quantities, reducing the requirement for excess inventory and products. Digital printing likewise makes use of less energy contrasted to conventional printing techniques. Digital printers do not call for as much power to operate, as they do not need to warm up as a lot or use as much power to run.

Digital Printing for Dummies

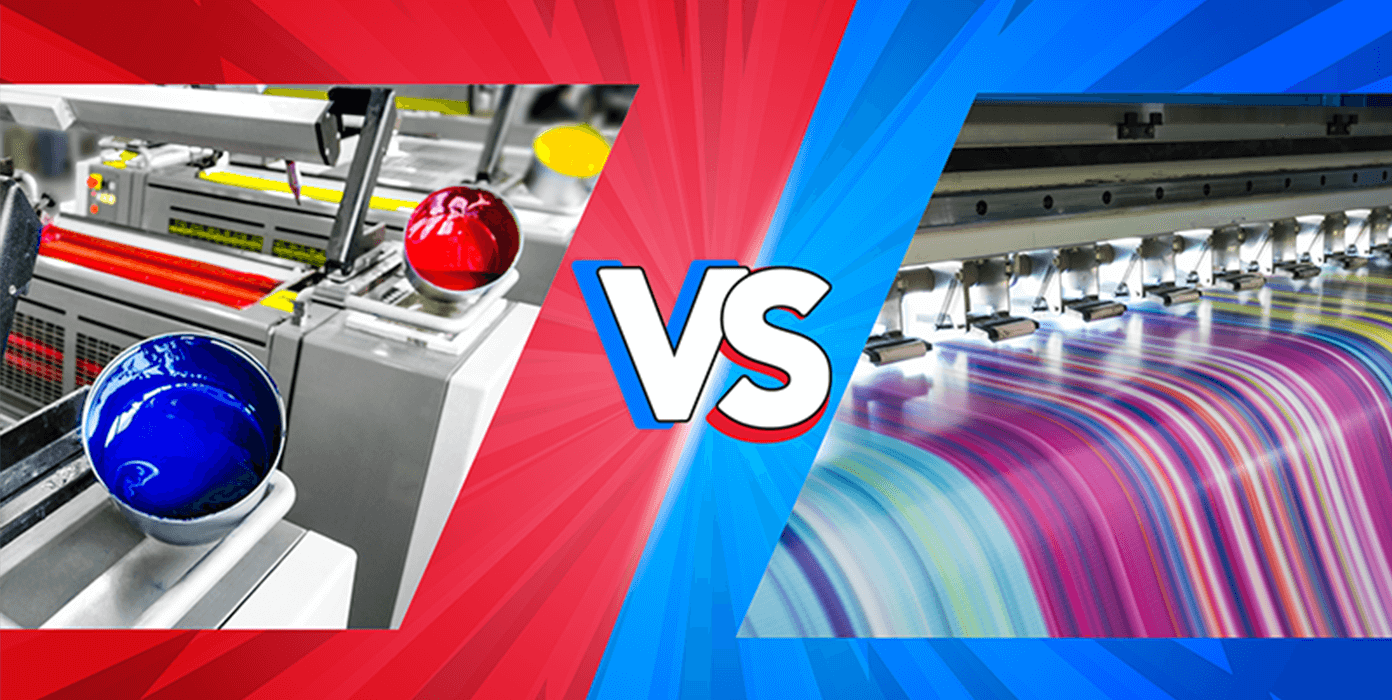

Offset printing needs a plate for each shade printed. Standard offset printing is a print method that makes use of light weight aluminum plates to move ink onto a rubber sheet (typically described as a "covering"). The photo is then rolled onto the printing surface area. This printing approach is thought about "balanced out" since the ink is not moved to the paper straight.

Get This Report on Digital Printing

Offset printing allows for a wide variety of print materials to be used during production. The premium photos produced with offset printing make it the preferred method, particularly among visuals designers, when seeking the best color reproduction, information, and professional-looking prints.

For digital inkjet printing, ink is transferred directly onto the surface area. Instead than counting on aluminum plates and rubber blankets to transfer a photo, electronic printing uses fluid ink throughout manufacturing.

The 7-Minute Rule for Digital Printing

Since offset printing can mix custom color inks for each job, it will naturally get the colors spot-on. Count on offset printing for clean, distinct types and pictures without streaks or areas.

It sets you back a great deal to begin a countered task. You need to spend money right into developing home plates, which takes time. Nonetheless, when you've spent it, all of the products prepare to go, and you'll spend less on huge balanced out jobs than an electronic print, which has Click Here to do with the exact same per item despite how big the work gets.

Digital printing is less costly for low-volume work. The price per device drops for digital printing, so at some point, they crisscross. Changing info within a single print work.

The Digital Printing Statements

While digital printing or inkjet printing is the preferred choice in the present times, there are compelling reasons to convert from countered to electronic printing systems. When printing balanced out or digitally, critical decisions and procedures are entailed in shade matching.

Industrial inkjet printing offers versatility for printing on many different substrates. Digital printing is excellent for clients who do not call for longer runs and warehousing materials.

One advantage of electronic printing is picking from a vast array of electronic substrates. With countered printing, substrates compose, typically, 30% of the price of the task. With digital printing, the price of the substratum in the overall work is tiny. This permits for more choices than in the past, and that's excellent for marketing professionals and companies.

Top Guidelines Of Digital Printing

drop-on-demand is the 2nd printing innovation to think about. Constant inkjet systems require considerable maintenance, even more driver training, Recommended Reading and greater downtime. Nonetheless, tools costs in inkjet printing are far less than countered printing as there are no plate-making, plates, and press expenses. Past the capital spending, the prepress equipment and printing machine require highly knowledgeable his response drivers in countered printing, which includes labor expenses.

Report this page